बाषà¥à¤ªà¥à¤à¤°à¤£à¥à¤¯ à¤à¥à¤²à¤¿à¤à¤ पà¥à¤¡

Price 1360 आईएनआर/ टुकड़ा

MOQ : 100 टुकड़ाs

बाषà¥à¤ªà¥à¤à¤°à¤£à¥à¤¯ à¤à¥à¤²à¤¿à¤à¤ पà¥à¤¡ Specification

- उपयोग

- औद्योगिक

- मटेरियल

- अन्य

- टाइप करें

- साइज

- 600 standard width

- प्रॉडक्ट टाइप

- ठंडा करने वाला पैड

- रंग

- Green/Brown

- चौड़ाई

- मिलीमीटर (mm)

- फंक्शन

बाषà¥à¤ªà¥à¤à¤°à¤£à¥à¤¯ à¤à¥à¤²à¤¿à¤à¤ पà¥à¤¡ Trade Information

- Minimum Order Quantity

- 100 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- 7 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About बाषà¥à¤ªà¥à¤à¤°à¤£à¥à¤¯ à¤à¥à¤²à¤¿à¤à¤ पà¥à¤¡

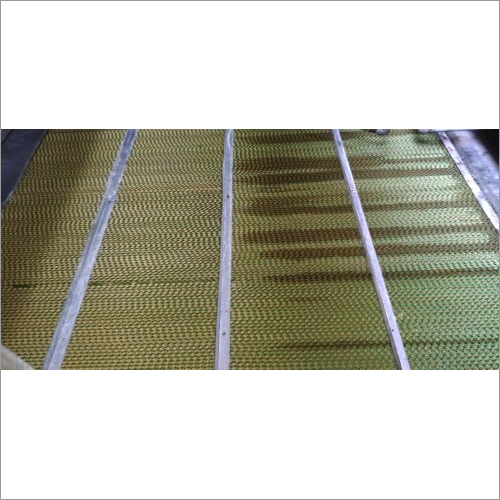

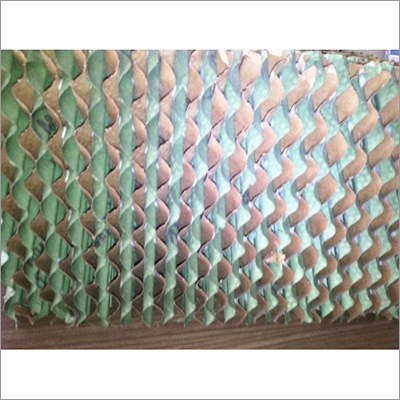

Cellulose pads or Honeycomb pads are made of paper unlike the traditionally used straw material. Water is made to pass through it via a header pipe having holes. Water trickles down the pad section very slowly thus forcing it to evaporate and mix in the air supplied by the blower finally making it cool. This is the concept of evaporative cooling. These pads come in various thickness depending on the efficiency required. They are also known as Celdek Pads or simply as evaporative cooling pads.

Wide-Ranging Applications

Evaporative Cooling Pads are suitable for use in factories, warehouses, homes, restaurants, offices, and both industrial and residential settings. Their versatile functionality ensures they are ideal for anyone seeking a cost-effective cooling and ventilation solution.

Efficient Ventilation and Cooling

These pads utilize the natural process of evaporation to lower temperatures efficiently while maintaining a steady flow of fresh, cool air. Their industrial-grade design supports enhanced ventilation, which is especially valuable during Indias warmer months.

Robust Design and Simple Installation

With a 600 mm standard width and available in green or brown, the pads are easy to integrate into various cooling systems. Manufactured with durability in mind, they require minimal maintenance and ensure long-term resilience.

FAQs of Evaporative Cooling Pad:

Q: How do evaporative cooling pads work for ventilation in industrial and commercial facilities?

A: Evaporative cooling pads are designed to draw hot air through their wetted surface, causing water to evaporate and cool the air. This cooled air is then circulated, significantly improving ventilation and lowering indoor temperatures in spaces like factories and warehouses.Q: What is the installation process for a 600 mm wide evaporative cooling pad?

A: The 600 mm standard width pads are typically installed within a cooling or ventilation system framework. They can be easily fitted and secured by following the manufacturers instructions, making them suitable for both new installations and retrofits in existing systems.Q: When should I replace my evaporative cooling pad?

A: Replacement frequency depends on usage intensity and water quality, but pads generally need inspection every 6 to 12 months. Replace the pad if there is visible damage, loss of thickness, or diminished cooling performance.Q: Where can these cooling pads be effectively used?

A: Evaporative cooling pads are effective in a variety of environments including factories, industrial plants, warehouses, restaurants, offices, as well as residential and commercial properties. Their versatility allows them to meet ventilation needs across different sectors.Q: What are the primary benefits of using industrial-type evaporative cooling pads?

A: Key benefits include energy efficiency, environmentally friendly cooling, improved air quality, and lower operating costs. They provide an effective alternative to traditional air conditioning in large, open spaces.Q: How does color choice (green/brown) impact the performance or aesthetic of the cooling pad?

A: While green and brown options primarily refer to the pads appearance and help blend with various building aesthetics, the color does not impact the cooling performance or efficiency of the pad.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें